Ceramic Hollow Spheres Insulating Bricks Bubble Alumina Insulating Brick

Description

Basic Info

| Bulk Density g/cm3 | 1.4-1.7g/cm3 |

| OEM | Yes |

| Application | Metallurgy |

| Apparent Porosity% | 58-62 |

| Max Service Temperature °c | 1800°c |

| Cold Crushing Strength MPa | More Than 9 |

| Sample | Provide |

| Certification | ISO9001:2008 |

| Advantage | Long Life |

| Transport Package | Wooden Box |

| Specification | Customizable |

| Trademark | RSNC |

| Origin | China |

| HS Code | 690220000 |

| Production Capacity | 5000t/Year |

Product Description

Ceramic Hollow Spheres Insulating Bricks Bubble Alumina Insulating BrickProduct Description

Introduce of Alumina Hollow Ball Brick

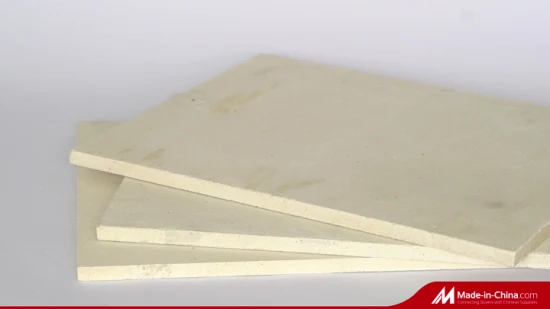

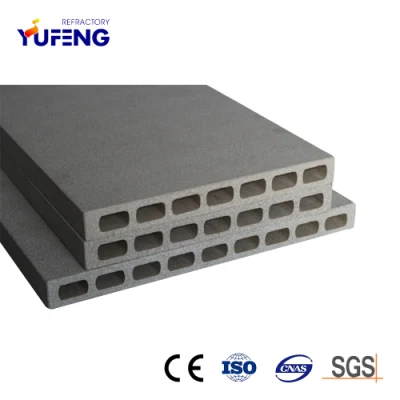

Alumina Bubble Brick is a new type high temperature heating insulation materials and made of industrial alumina in the electrical furnace through smelting and blowing. Alumina Bubble Bricks' crystal form is a-Al2O3 microcrystal and main body is alumina bubble that can be made to be all kinds of products with various shapes for serving the highest temperature of 1800ºC with high mechanical strength and low bulk density.Alumina Bubble Brick Specifications:1. High purity;2. High mechanical strength;3. Low thermal conductivity;4. Good stability5. Mainly apply to the insulation layer of coal-water slurry gasifier6. Excellent thermal insulation7. Long service life8. High compressive strength9. Competitive priceSpecification

Technical Data of Alumina Hollow Ball Brick

| Item | Alumina Bubble Brick | |||

| Types | Unit | 85# | 90# | 99# |

| Maximum Service Temperature | ºC | 1680 | 1700 | 1800 |

| Al2O3 | % | ≥85 | ≥90 | ≥99 |

| SiO2 | % | ≤15 | ≤8 | ≤0.2 |

| Fe2O3 | % | ≤0.2 | ≤0.2 | ≤0.2 |

| Bulk Density | g/cm3 | 1.4-1.7 | 1.4-1.7 | 1.4-1.7 |

| Cold Crushing Strength | MPa | ≥12 | ≥10 | ≥9 |

| Refractoriness Under Load (0.1MPa, 0.6%) | ºC | ≥1650 | ≥1760 | ≥1760 |

| Reheating Linear Change (1600ºC*3h) | % | ±0.3 | ±0.3 | ±0.3 |

| Thermal Expansion Coefficient (Room temperature -1300ºC) | ×10-6ºC-1 | ~7.8 | ~8.0 | ~8.6 |

| Thermal Conductivity (Average temperature 800ºC ) | W/(m·K) | ≤0.8 | ≤1.3 | ≤1.5 |

Product Application

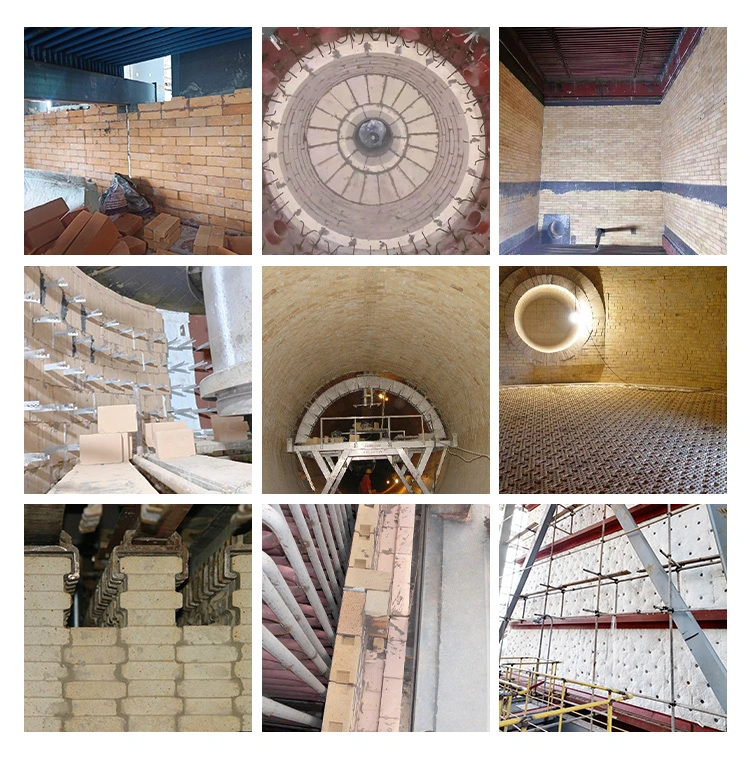

Application of Alumina Hollow Ball Brick Alumina Bubble Brick is a kind of very important refractory material for resisting high temperature and special demands of positions for furnace and kiln, which is mostly used as insulating brick for insulation layer of furnace and kiln, and also can be used for service linings in manufacturing high-purity quartz for the electronics industry such as ceramic tile linings in gas turbines and backup linings in reactors.

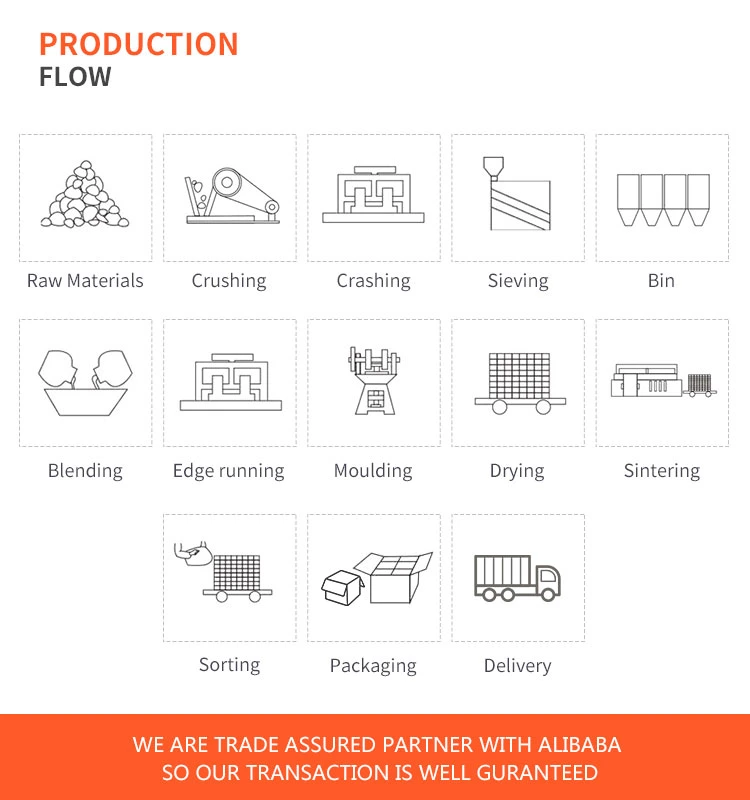

Production Process

Packaging & Shipping

Packaging : Packed by sea-worthy wooden pallet + shrink wrapped + carton For example, Standard size of Fireclay brick : 230x114x65mm Shipping : 384pcs/plt x 18plts in one 20 feet container;

Company Profile

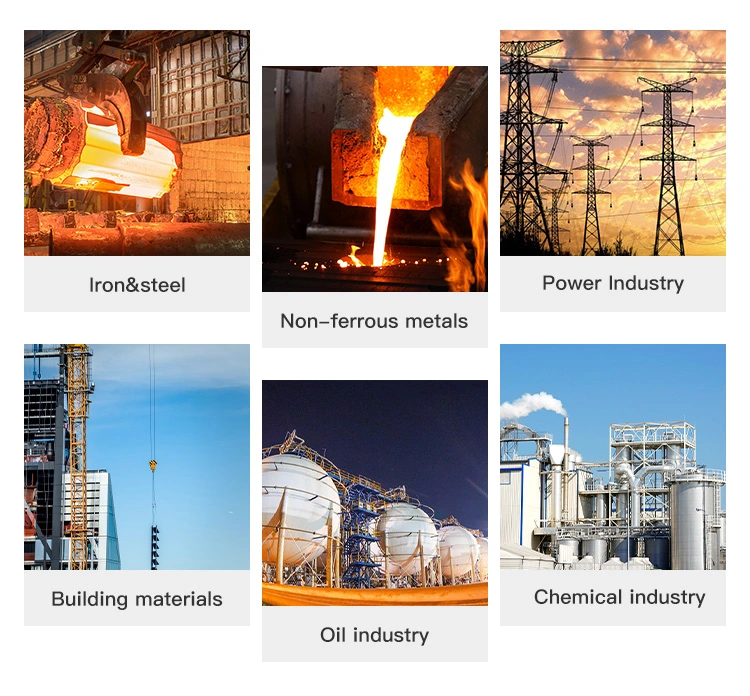

RS Refractories is located in Henan, China. Our company has professional scientific and technical personnel and production team, and we have our own fully automated factories. For more than ten years, we have focused on the development and innovation of refractory materials and high-temperature furnace technology, and strive to provide customers with comprehensive, personalized and cost-effective services with high-quality products. Our products are widely used in electric power, metallurgy, petrochemical and other fields, and are exported to more than 70 countries and regions in the world such as Europe, America, Oceania, Southeast Asia, and the Middle East.

RS Refractories is a first-class supplier of refractory materials, we can provide you with the most advantageous quotations and products. Looking forward to be your partner

Certifications

FAQ

Q1. Are you Manufacturer?A: Yes, of course, our factory is in Xinmi,zhengzhou city,Henan province.Q2. Can we visit your company?

A: Sure,welcome at any time,seeing is believing.Q3. Do you accept OEM?

A: Yes, we can do OEM.Q4. What's the MOQ of trial order?

A: No limit,We can offer the best suggestions and solutions according to your condition.Q5. What are the payment terms?

A: Usually T/T,but L/C,Western Union etc are available for us.Q6. How long is delivery time?

A: The delivery time will be determined according to the quantity of the order.Q7. How are your products' quality?

A: The products will be strictly inspected before shipment, so the quality could be guaranteed.Q8. How to solve the quality problems?

A: If the products are not confirmed to customer samples or have quality problems,our company will be responsible to make compensation for it.Q9. What is the service life of your bricks?

A: The service life of different bricks is unlike.It also depends on your using condition and method.Q10.How about your company's certification?

A: ISO9001 and Test Report,also we could apply other necessary certification.

Prev: Light Weight Insulating Brick High Alumina Insulating Bubble Brick for Industry Furnace

Next: High Temperature Thermal Insulating Light Weight Fire Brick

Our Contact