Magnesite Spinel Refractory Brick for Cement Plant

Description

Basic Info

| Model NO. | MGAL-85 |

| Al2O3 | at Least 9.0% |

| Cao | No More Than 1.5% |

| Sio2 | No More Than 1.0% |

| Fe2o3 | No More Than 0.8% |

| Thermal Shock Resistance | 1100ºC, Water Cooling, at Least 8 Cycles |

| Cold Crushing Strength | 55~80 MPa |

| Refractories Under Load | 1700ºC |

| Transport Package | Fumigation Pallets |

| Specification | B422, B322, B622, P22, P+22 |

| Trademark | Fireramo |

| Origin | China |

| HS Code | 6902100000 |

| Production Capacity | 80000 Tons Per Year |

Product Description

Brief Introduction of Magnesia Spinel Brick:Magnesia Spinel Brick is mainly made of periclase and magnesia spinel, which can improve the heat stability of common magnesia brick.Application of Magnesia Spinel Brick:It's mainly used for burning zone and transition zone of cement kiln, also some other industrial furnaces.Feature of Magnesia Spinel Brick:

- Excellent Heat Stability

- Better Anti-stripping performance than direct bonded magnesia chrome brick

- Abrasion Resistant

- High Refractoriness Under Load

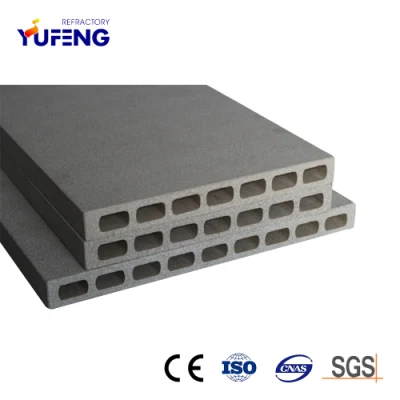

Dimensions of Magnesia Spinel Brick:The common used dimensions for them are according to VDZ standard of bricks for rotary kiln.

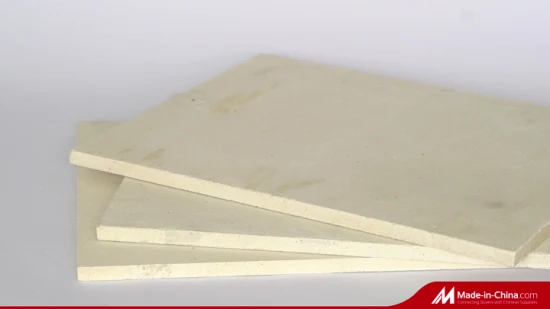

Detailed Photos

Product Parameters

Chemical & Physical Properties of Magnesia Spinel Brick:

| Item | Unit | Magnesite Spinel Brick | |

| MGAL-85 | |||

| Bulk Density | g/cm3 | 2.92±0.05 | |

| Apparent Porosity | % | ≤18 | |

| Cold Crushing Strength (C.C.S.) | MPa | ≥ 55 | |

| Refractoriness Under Load | ºC | ≥1700 | |

| Thermal Shock Resistance(1100ºC, water cooling) | cycles | ≥ 8 | |

Chemical Composition | MgO | % | 85~89 |

| Al2O3 | % | ≥9.0 | |

| Fe2O3 | % | ≤0.8 | |

| SiO2 | % | ≤1.0 | |

| CaO | % | ≤1.5 | |

Packaging & Shipping

Packing Method:a. bricks will be stacked on the export wooden pallets in orderb. there will be paper sheets between each layer of bricksc. Orderly placed refractory bricks are wrapped around by plastic film to be waterproofd. Eventually the four sides and top will be reinforced with plywood to prevent collisionse. Pallet size no more than 1100x1100x1100 mmPacking Photos:

Company Profile

Brief Introduction of Fireramo:

Fireramo is a new technology enterprise specializing in manufacturing, production, sales and consultant of refractory materials for various industry, such as, cement plants, glass factories, steel plants, chemical & oil industries.The factory of Fireramo covers an area of 108,000 Square Meters with more than 1 billion RMB fixed assets. There are around 400 employees in our factory, including 5 board members, 10 technicians, and 4 plant managers. We have the advanced and standardized raw material selecting equipment and production equipment.

Our Advantages

- Around 30 years history for producing and supplying refractories for high temperature industries

- Advanced raw materials selection, production and packing equipment

- Professional and responsible technical, engineering and sales team

- First-level management team and R&D team

- The location of Central Plains Hub to ensure convenient transportation

- Self-own logistics team to ensure the timeliness of transportation

- Timely and effective after-sales service team

Prev: Blast Furnace High Alumina Brick

Next: Lightweight Mullite Brick Insulation Fire Jm23 K23 Insulating Firebrick

Our Contact