Silicon Carbide Sisic Burner Nozzle Tube as Kiln Furniture Applying Germany Technology

Description

Basic Info

| Model NO. | customers′ requirements |

| model number | SISIC |

| SiC Content (%) | 83.66% |

| Density | under 3.02 g/cm3 |

| Open Porosity | <0.1% |

| Bending strength | 250MPa/280MPa |

| Modulus of Elastictiy | 330Gpa/300Gpa |

| Thermal Conductivity | 45W/m.K(1200 Celsius) |

| Coefficiant of Thermal Expansion | 4.5K-1*10-6 |

| Moh"s Hardness | 9.15 |

| Vickers Hardness HV | 20Gpa |

| Acid Alkaline-proof | Excellent |

| Length | Customer′s Required |

| Flange Width | Customer′s Required |

| Web Width | Customer′s Required |

| Transport Package | Wooden Box with Foam Inner |

| Specification | SISIC/RBSIC/SIC |

| Trademark | Weifang-Better |

| Origin | Weifang, China |

| HS Code | 6903900000 |

| Production Capacity | 5000PCS/Month |

Product Description

Silicon Carbide Sisic Burner Nozzle Tube as Kiln Furniture Applying Germany TechnologyRefractory Silicon Carbide ceramic burner nozzle / RBSIC burner tube/ SISIC burner sleeve Property:

◊ Excellent heat and wear resistance, impact resistance and corrosion resistance

◊ Excellent flatness and temperature resistance up to 1380ºC

◊ Excellent oxidation resistance

◊ Good dimensional control of complex shapes

◊ Easy installation

◊ Longer service life ( about 5 times more than that of alumina ceramic and 6 times more than that of polyurethane)

Photos of reference

Technical parameters of reaction bonded silicon carbide RBSIC :

| ITEM | UNIT | DATA |

| Temperature | ºC | 1380 |

| Density | g/cm³ | ≥3.02 |

| Open Porosity | % | <0.1 |

| Moh's Scale of Hardness | 13 | |

| Bending Strength | MPa | 250 (20ºC) |

| MPa | 280 (1200ºC) | |

| Modulus of Elasticity | GPa | 330 (20ºC) |

| GPa | 300 (1200ºC) | |

| Thermal Conductivity | W/m.k | 45 (1200ºC) |

| Coefficient of thermal expansion | k-1×10-6 | 4.5 |

| Acid Alkaline -proof | Excellent |

Our Exhibition

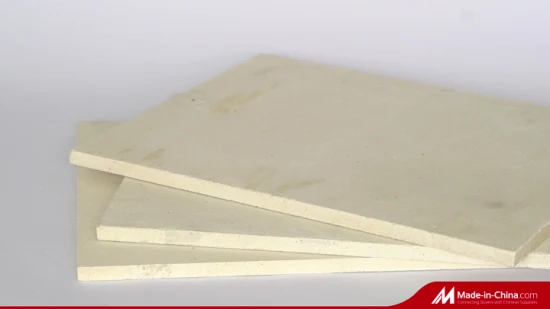

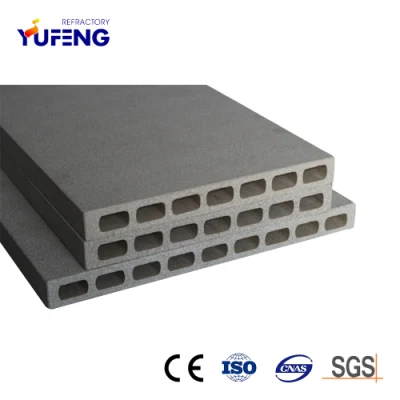

Related products and Specifications of RBSIC ceramic

Thickness available: 6mm - 25mm

Shape available: screw, plain plate, straight pipe, tee pipes, ring, elbow, cone cyclone and so on.Remark: Other sizes and shape are available upon requests.

Production factory

Packing & Delivery:

Packaging Details:(1) Export safe wooden box(2)Inner boxes with filler .(3)Out package is high quality cartons .(4)Custom packageDelivery time:Within 5 days after getting the full payment

Company information

Weifang Better ceramic CO., LTD. Is a professional enterprise in the production of reaction sintered silicon carbide ceramics. The silicon carbide products produced by the company have stable performance and excellent quality, and have passed ISO9001 quality system certification. The main products of the company are: silicon carbide beam, silicon carbide roller, silicon carbide burner sleeve, radiating tube flame guide sleeve, silicon carbide cold air tube, reflecting sintered silicon carbide cantilever paste, silicon carbide crucian sagger, silicon carbide inner liner of cyclone, desulfurization nozzle.The product has high strength, high hardness, high temperature resistance, wear resistance, corrosion resistance, oxidation resistance, rapid cooling and heat resistance, thermal shock resistance, good thermal conductivity, high thermal efficiency.The products are widely used in power plant desulfurization and dust removal equipment, ceramic high temperature kiln, steel mill quenching furnace, mining material classification cyclone.Our team

We are a professional team.Our members have many years of silicon carbide technology and research.We are a young team.We are full of youthful spirit and innovative spirit.We are a dedicated team.We firmly believe that the best brand name comes from the trust of the customers.Only focus, will make better products.We are a dream team.We come from all over the world, as a common dream: to be a really good silicon carbide production manufacturers.Effective team members for the team to show high levels of loyalty and commitment, intended to allow a group to be successful, we are willing to do anything."We put the loyalty and dedication, called consistent commitment.

What can we do for you

1. Sample is available.2. Independent R&D, ISO manufacture, precise quality standards, modern logistics management, and sound marketing strategy.3. Inquiry replied within 24 hours.4. Patented products.5. OEM or ODM is available.6. Some extra accessories can be supplied.7.The larger quantity you order,the more competitive prices you'll get.8. Necessary Certificates can be supplied.

FAQ

Q: Are you trading company or manufacturer ?

A:We are factoryQ: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 25-30 days if the goods are not in stock, it is according to quantity

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance ,balance before shippment.

Our Contact